Powder Coating Delta

Serving Greater Vancouver, and worth the drive!

(pick up and drop off available)

24 hr Rush Service, if doable on any given day.

5° Five Degree Powder Coating was started to give clients the extra care that is missing in the industry. Typically the client would need to wait for a shop to run the colour they desire, which leaves them at the mercy of the shop’s schedule.

Our mission is to deliver hands-on attention and treat each job as a custom job. 5° can repair most steel or aluminum parts and deliver a flawless, durable finish. All parts are chemically stripped, sandblasted and powder coated. The sky is the limit with so many colours available to choose from.

Specializing In Powder Coating Automotive & Motorcycle Parts. We Can Powder Coat Other Parts Upon Request. Just Ask.

5° Five Degree Powder Coating hopes to earn your business.

Email Us

Let us know how we can help you.

BOOK AN APPOINTMENT

Working Hours

Monday – Friday: 7:00 am – 6:00 pm

Saturday: 8:00 am – 4:00 pm

Sunday: CLOSED

Contact Us

CALL US

What do we stand for?

Why Choose Five Degree For your Powder Coating needs?

Five Degree Stands For the Following 5 Core Values:

- Integrity – We are firm believers in doing what we say we will do. You can always expect us to deliver the goods as advertised!

- Accountability – We take full responsibility for the projects we take on and the results that we deliver. We are reliable and stick to the timelines.

- Quality – We are proud of our very high standards and our clients can always expect exceptional results. Customer satisfaction is always guaranteed, we make sure of it!

- Cleanliness – It all starts with a clean workspace, we always maintain a clean workshop which translates into our quality of work.

- Creativity – We are creative and do not follow the crowd. We truly believe there is always a better way to do something and continually work on improving our craft.

Almost all metal objects that can hold an electric charge, can be powder coated. Steel, mild steel, aluminum, stainless steel, galvanized steel, and most other steel alloys are all excellent candidates for powder coating. Due to its high durability, powder coating is a popular process, especially for automotive and motorcycle parts that have absorbed some decent wear and tear over the years. The results are amazing and objects appear as good (if not better) than new!

Powder coating is also available in over 6000 colors which not only allows for customization but makes any powder coated parts look brand new all over again!

Sandblasting is a good practice to perform on most parts, no matter what condition they are in. It helps form a good surface for your selected paint colours to bond and helps remove any foreign materials and imperfections for a beautiful finish.

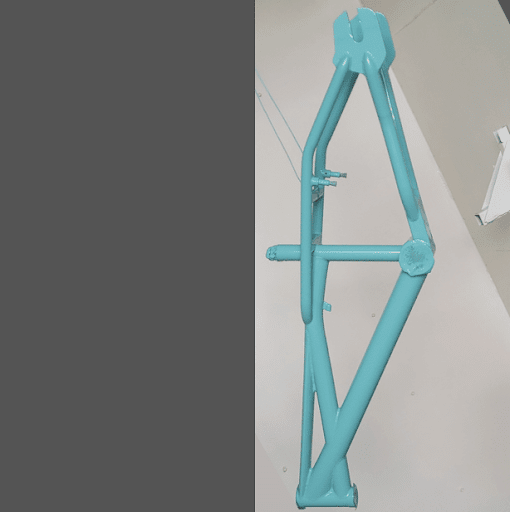

The most common automotive parts people powder coat are valve covers, wheels & rims for cars and trucks, radiators, as well as motorcycle frames, tanks and rims. Marine parts, light fixtures and much more…the possibilities are almost limitless so if you are thinking of powder coating something specific, do not hesitate to reach out for more details.

Jeff

ULTIMATE RESTORATION

with Unlimited Colours

Core Skills

Sandblasting

Sandblasting involves shooting media using compressed air to roughen or clean an object. This is generally done in the refinishing of most steel or aluminum parts. Sandblasting media can be crushed walnut shells, glass beads or aluminum oxide. It is the best way to prep any part before painting.

Powder Coating

Powder Coating is a high quality finish that is applied using a spray gun with an electrostatic charge. It is a free flowing dry powder that is charged with a grounded metal substrate, then cured in an oven at around 400 degrees. The final product is a surface that is more durable than what regular paint processes can provide. It is more resistant to scratches, chipping and is more cost effective and environmentally friendly. Click on the following link to learn more details about our powder coating services and why it is gaining popularity!

We also do Cerakote, a line of ceramic-polymer hybrid coatings that is designed to provide unmatched performance with an attractive and desirable finish.

Frequently Asked Questions

What is Sandblasting?

Sandblasting involves shooting media using compressed air to roughen or clean an object. This is generally done in the refinishing of most steel or aluminum parts. Sandblasting media can be crushed walnut shells, glass beads or aluminum oxide. It is the best way to prep any part before painting.

What is Powder Coating?

Powder Coating is a high quality finish that is applied using a spray gun with an electrostatic charge. It is a free flowing dry powder that is charged with a grounded metal substrate, then cured in an oven at around 400 degrees.

The final product is a surface that is more durable than what regular paint processes can provide. It is more resistant to scratches, chipping and is more cost effective and environmentally friendly.

How long does it last?

What do you charge?

Project costs will vary. If you have larger items, those can be estimated on a per item basis.

For smaller projects, these can be grouped together in quantity to make it a project.

Do you have examples of your work?

Visit our Instagram page to view pictures of our work.

Before & Afters

SANDBLAST, REPAIR, POWDER COAT

5° POWDER COATING

change starts here

Reach Out

Ready to get started? Contact us today to experience the great

service and results working with 5° can provide you.

Reviews

Hours

- Monday 7:00 am - 6:00 pm

- Tuesday 7:00 am - 6:00 pm

- Wednesday 7:00 am - 6:00 pm

- Thursday 7:00 am - 6:00 pm

- Friday 7:00 am - 6:00 pm

- Saturday 8:00 am - 4:00 pm

- Sunday closed